Manufacturing tour an eye-opener for Ronan students

Hey savvy news reader! Thanks for choosing local.

You are now reading

1 of 3 free articles.

When a drill bit is purchased anywhere across the globe, there’s a good chance it’s made in Ronan.

“It seems most of the bits we use in the industry are built here,” Reese McAlpin, Ronan High School agriculture and welding instructor, said after the Friday tour of Rocky Mountain Twist/Jore in recognition of National Manufacturing Day.

The tour was an eye-opener for 60 Ronan students who were presented with career possibilities for both college-bound or trade-bound graduates.

Freshman Dylan Wilson said he now has a new respect for the company.

“I pass by this everyday and thought it was just an assembly line,” he said.

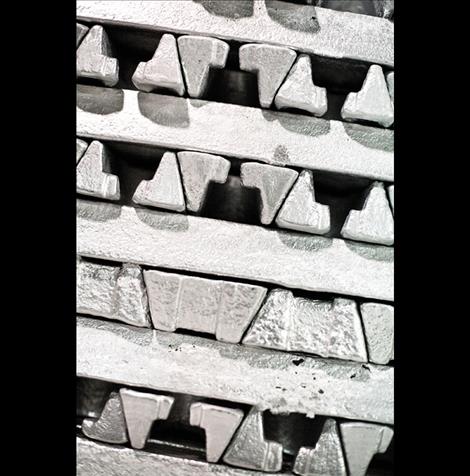

Not so. It takes a team of 180 people working around the clock to produce 40,000 drills per day — 14 million per year — at the local manufacturing plant.

Students interacted with representatives who demonstrated how the teamwork process successfully connects every department from accounting, marketing, design, production, quality control and shipping.

RMT/Jore design engineer Nathan Cantlon, a graduate of Ronan High and Montana State University, left the area for college but chose to return to his hometown for his career.

“Engineering is problem solving,” Cantlon explained. “It’s a good job for a tool junkie.”

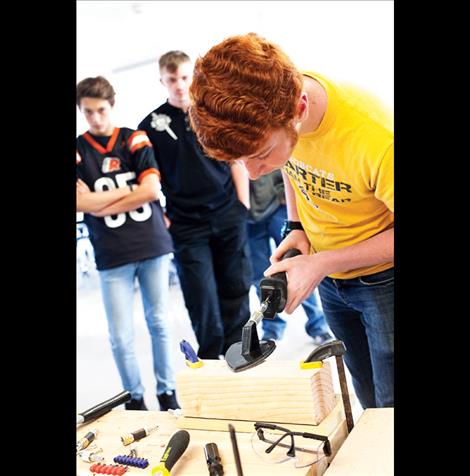

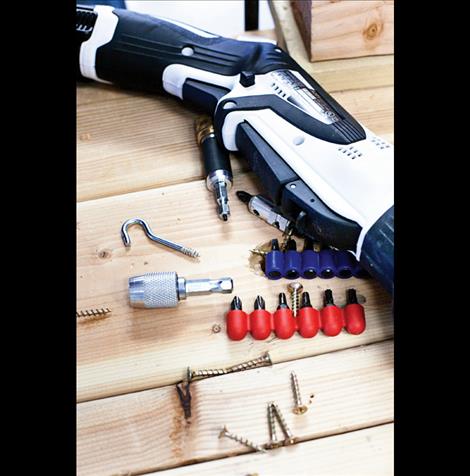

Cantlon has more than dozen patents to his credit. One of the newest patents hitting retail shelves in about two months is a drill for attaching cup hooks and eye bolts, one of the tools he demonstrated as he allowed students to try some of the products on a block of wood.

In the hands-on station, Ronan student Jacob Dresen used a variety of drill bits to drill a hole, create a wood “cork,” tap the cork into the hole with a rubber mallet, saw the top flush and then sand it down.

“You’re hiding your tracks so you can’t see your screw,” explained Dresen, a sophomore who plans to study mechanical engineering at MSU.

RMT/Jore makes “well over 10,000 variations of drills” and at least 2,500 custom drills “that you won’t see at Home Depot,” Cantlon said.

Their retail product is sold throughout the world, marketed under names such as Sears’ Craftsman brand, Lowes’ Kobalt brand, Costco’s Maxbuilt brand, Hitachi, Makita and DeWALT.

“There’s two legs to who we are,” said manufacturing manager Dustin Hess, “retail and industrial.”

Industrial buyers include aerospace companies like Boeing and United Airways plus several auto makers.

“It’s neat to see our local company in the big time,” said Tracy Pagel, director of sales and marketing for RMT/Jore, crediting the graphics team for helping sell the product. “Their main emphasis is to put the products in a good light and make (people) want to purchase them.”

Senior designer Clint Henriksen’s artwork can be seen in everything from the company’s website to photography, marketing banners and tool case design. With a bachelor’s degree in fine arts, Henriksen made graphic design relevant to the students by showing examples of designs created on snowboards, car wraps and football helmets.

Students also toured areas of production where massive machines turned chunks of steel into meticulously-machined products; where words such as blanking, swedging, deburring and brazing made sense to the hard-working crew.

“The tour showed me how different things are made. People make these machines to make tools,” sophomore Chris Books said.

A random sampling of a dozen drill bits pulled from a lot of 3,000 must pass quality control before they are shipped. Drill samples go through a rigorous checkup that includes a hardness tester, a rotating gauge to determine if the bit is truly straight, and an x-ray scanner to determine what chemical compounds are in the steel. Every grinded feature is checked, including all 28 dimensions on a drill bit. Students seemed especially interested in the Lo-Torq machine.

“We’ve destroyed a few (drills) in there,” Hess explained, “and then based our design on the results to increase the strength of the part.”

Sophomore Coleman Taylor said he was impressed with an innovative quick-change design that was born as the result of an accident. After Jore Corporation founder Matt Jore lost the use of one of his hands, a one-handed quick-release system for drills was born, replacing the old key-style chuck.

The students returned to school with additional tools to use in their shop classes, courtesy of RMT/Jore.

“We have a phenomenal team of 180 people that come together every day to make this happen,” said Tiffani Kinaman, human resources manager.

While the local tour took place Friday, the National Manufacturing Day is held each year on Oct. 2 as companies across North America open their doors to students, faculty and parents. More than 2,000 Manufacturing Day events are scheduled in all 50 states, Puerto Rico, Canada, and Europe open their doors for events.